|

Hangzhou Schroeder Technology Co., Ltd.

|

Gold Index: 6809

750 Micron Wedge Cylindrical Screen / Non - clogging Professional Johnson Screen

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

750 Micron Wedge Cylindrical Screen / Non - clogging Professional Johnson Screen

<span style="font-

750 Micron Wedge Cylindrical Screen / Non - clogging Professional Johnson Screen

Item Code:750MICRON-OD45FOTI

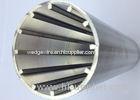

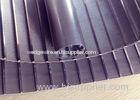

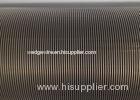

750 Micron Large Open Area And Non-clogging Surface Wire Wrapped Screen is an effective method of filtering because of the non-clogging capabilities due to the wedge shape of wire.Wedge wire is produced in a range of sizes;such as head width and profile depth with the latter having various side angles to suit a wide range of applications.

|

Profile Wire |

W |

H |

|

10SR |

0.75 |

1.425 |

|

12SR |

1 |

2 |

|

18SR |

1.52 |

2.54 |

The wedge wire is continually wound around a set of support rods which are either shaped or round.The wire rod configuration can be designed to suit your particular needs.

We have heavy wedge wire profiles in either 304 or 316 grade stainless steel for applications involving coal or iron ore processing or much lighter profiles which give more open area for filtering fine solids from liquids.Whatever your situation calls for ,we can provide you with a wedge wire screen designed to your own specifications.

Wedge wire screen provide a unique combination of the most important features required for maximum screening efficiency.The product is custom designed to suit the specific requirements of the customer and to enable a relatively low cost and high performance solution for the screening application. The high open area of the Wedge Wire screen provides excellent capacity.

Construction

Applications:

|

Applications of wedge wire screen

|

|||

|

Liquid / Solids Separation

|

Sizing, Straining and Filtering

|

Collection

|

Retention |

|

Solids removal from process wastewater

Lake and riverwater intake screens Fiber removal Screen cylinders for rotary screens Recovering solids Pulp thickening Heavy media recovery Product dewatering Sieve Bend Screen surfaces |

In-line strainers to minimize the lose of media

Resin Traps used as an effluent strainer Sizing of solids Pressure screens Filtering particles from treated fluid Strainers for pump or compressor protection |

Support grids for uniform fluid collection in media filter

Hub lateral screen systems Header lateral screen systems Collection of treated liquid in treatment vessels Filter nozzles for tube sheets Upflow Clarifiers Gravity filter underdrain systems |

Retaining media and collecting the treated liquid

Carbon retention screens in carbon-in-pulp tanks Flooring for germination, malt kiln, grain drying rooms Catalyst retention in catalytic reactors Fish protection / diversion screens |

End connection:

Plain beveled ends for butt welding (welded ring) or

threaded male &female coupling.(spiral)

Our advantage:

1. We are manufacture.

2. We have advanced proccessing machine.

3. We can make slot screen tube perfect round

4. We can do the slot 0.02mm minimumly.

5. Professional sales team can give you feedback within 24 hours.

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Hangzhou Schroeder Technology Co., Ltd. [China (Mainland)]

Business Type:Manufacturer

City: Hangzhou

Province/State: Zhejiang

Country/Region: China (Mainland)